My Story

Begha is a leading developer of A-grade commercial, industrial and residential projects

in USA. Since its foundation the company has doubled its turnover year on year, with

its staff numbers swelling accordingly.

Always Available

all construction sites open for visitors, with 24/7 video surveillance being conducted at all objects

Qualified Agents

We have a team of specialists capable of maximizing the result and delivering the projects

Fair Prices

you can be 100% sure that it will be delivered right on time, within the set budget limits

Best Offers

All aspects of the operations being transparent and clear for clients and partners

Our Services

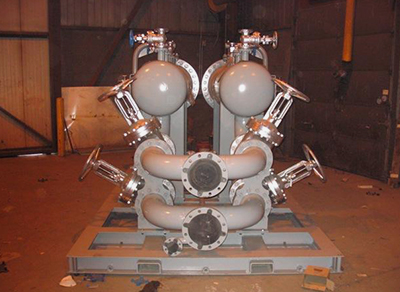

Heavy Plate Rolling

Plants & Machines

Welding & Metallurgy

My Projects

Why Choose Me

We do only what we are great on. If we tackle a project you can be 100% sure that it will be delivered right on time, within the set budget limits and at the top level. We get all our liabilities insured, including third-party liabilities, thus indemnifying our clients against all risks.

We do only what we are great on. If we tackle a project you can be 100% sure that it will be delivered right on time, within the set budget limits and at the top level. We get all our liabilities insured, including third-party liabilities, thus indemnifying our clients against all risks.

We do only what we are great on. If we tackle a project you can be 100% sure that it will be delivered right on time, within the set budget limits and at the top level. We get all our liabilities insured, including third-party liabilities, thus indemnifying our clients against all risks.

RELIABILITY

Yellow Hats has a cutting edge quality management system which ensures high quality standards at all sites.

EXPERTISE

We have a team of specialists capable of maximizing the result and delivering the projects of any complexity and scope.

QUALITY

The control mechanism allows secure & integrated monitoring of all stages of the works.

Testimonials

Dear MR. Hooper,

On behalf of Petro-Canada. I am writing to thank you for the support that Hooper Welding Enterprises Ltd provided during our 2003 HTU incident at our lubricants Center.

As you are aware this incident was unexpected, and without notice, demanding the immidiate response of Petro-Canada personel and its entire supply base for the immediate provisions of materials and Services.

The excellent response provided by your staff helped us all to meet the challenges required to practically ‘re-build’ a complete process unit in record time. The people at Hooper Welding enterprises Ltd, should be proud of their performance towords this accomplishment.

Petro-Canada relies heavily on suppliers and service providers to run a safe and productive operation. This untimely incident has once again confirmed that without the support of companies such as yours, we would not have been successful.

Please pass on our sincere thanks to all concerned.

Yours truly,

Robert j Major

Maintenance Manager

Petro-Canada Lubricants Centre

John D’Alessandro

Purchasing Agent

Petro-Canada

To Whom It May Concern:

In January of 2006, Hooper Welding Enterprises Limited was contracted by Worley Parsons in Houston, Texas to fabricate (3) three desalter vessels for ExxonMobil’s pipestill 3 (PS3) and Pipestill 7 (PS7) projects in Baytown, Texas.

P.O. #157000-20127 was issued to fabricate Tag# DR-712 for PS3 while P.O. #157000-20134 was issued to fabricate Tag#s DR-723 and DR-724 for PS7.

Hooper Welding worked very close with WorleyParsons engineering to ensure that the vessels were fabricated to the highest quality standards and in compliance with all specifications. After completing fabrication, the vessels were successfully hydrotested and post weld heat treated. Hooper Welding subcontracted the installation of the internal electric grid systems which were provided by others. This work required a high level of coordination with a designated 3rd party inspector who was a specialist in this field. Next, a qualified subcontractor was selected to coat the vessels with thermal spray aluminum (TSA). Finally, the vessels were insulated by a qualified subcontractor at the Hooper facility in Oakville.

In addition to completing all(3) three desalters on schedule, Hooper Welding was involved in the difficult task of shipping these vessels via rail from Oakville, Ontario, Canada to ExxonMobil’s plant in Baytown, Texas, USA. All (3) three vessels arrived at ExxonMobil’s rail spur in Baytown, Texas without damage to the vessels or the insulation.

WorleyParsons congradulates Hooper Welding for a job well done and looks forword to working with Hooper Welding Enterprises limited on other projects in the future.

John peacock

WorleyParsons

Project Procurement Manager

Dear Chris:

I wanted to express our appreciation for the great job you and Hooper Welding did on the coalescer and amine contactor vessels for Oneok. It was nice to receive vessels early for a change. The contactor vessels looked awesome with the nice shiny lagging, and insulating them in the shop saved a lot of time in the field. our fears of damage to the insulation during shipment proved unfounded.

We also appreciate the effort you personally went to work with the railroad to come up with a routing to the jobsite. thanks for the job well done, and we look forword to working with Hooper again on future orders.

Sincerely,

Burns & McDonnell

Earl/Chris,

This letter is written to express Flour Enterprises Inc.’s appreciation for Hooper Welding Enterprises Ltd.’s outstanding performance on the 2007 Moses Lake Expansion Project.

Hooper completed 36 small, but complex high alloy vessels for the project totaling US$1 million. In absolute difficult market conditions, hooper was one of the only fabricators on the Project able to meet their contractual delivery dates for the equipment. Hooper did so while not sacrificing quality or safety.

It was a true pleasure and success working with Hooper on the Project and I would highly recommend Hooper for any similar work in the future.

Best regards,

Lou DeArman

Fluor Enterprises Inc.

Project Material Manager

2007 Moses Lake Expansion Project

Dear Chris:

We want to take this opportunity to express our appreciation with the performance of Hooper Welding in the fabrication and delivery of the Debutanizer tower for CCRL in Regina. Your ability to meet a very aggressive delivery schedule allowed the project to achieve delivery prior to transportation restrictions and to meet a turn-around schedule.

rarely has a supplier provided such complete cooperation. The staff at Hooper consistently made every effort to ensure completion on time and in fact delivered ahead of schedule. We look forword to many more successful projects in the future.

Regards,

Colt Engineering (Ontario) corporation

Larry Foreman

Project procurement manager

To Whome It May Concern,

Hooper Welding completed the fabrication of a reactor for Frontier EI Dorado refining Company in july, 2010. The fabrication of the reactor took approximately 3 years to complete. As I understand, this is the largest thick wall vessel fabricated in North America. The reactor was 14.5 ft OD, 5.5″ thick, 106 ft T-T, and weighed 1,260,000#.

Hooper was the only North American company to bid on this reactor. They could fabricate this because of their knowledge in welding and their ability to think out of the box on how to handle rigging this weight during fabrication. Hooper brings tremendous knowledge and skills in welding. their equipment and skills for automated duo-feed welding and weld overlay capability also made this fabrication a success. The fabrication quality of this reactor was fantastic.

Hooper Welding and Frontier developed a good relationship over a period of 3+ years. Their abilities in heavy wall fabrication are unparalleled in North America.

My appreciation and thanks goes out to Hooper Welding.

Regards,

Tommy Woznick

Director of Major Capital Projects

Frontier Refining & Marketing, Inc.

To Whom It May Concern:

In late-2009 Petro-Canada Lubricants Inc undertook a project to upgrade three carbon 1/2 molybdenum pressure vessels to 1 1/4 chrome 1/2 molybdenum material. Through a competitive bidding process Hooper Welding Enterprises Ltd was selected based on price and delivery. As project manager the procurement, fabrication, delivery and installation of all three vessels was under my direct supervision.

From the initial contact through the final submittal of the as-built history docket, Hooper Welding delivered quality products on budget andon time. As a result of there efficient and effective work, the insulation and fireproofing of these vessels as well as the fabrication of new platforms was added to there scope. All components of this work were executed to the satisfaction of our third party inspector and the project team.

In addition to the quality products received, Hooper Welding impressed by supporting the installation of these vessels in the field during our turnaround in October 2010. This included, but was not limited to, supporting the installation of platforms and procurement of additional loose materials that were misplaced in the field.

Since the completion of this project I have had the pleasure of working with Hooper Welding on several smaller projects and the quality of there workmanship has continued to impress. I have personally recommended Hooper Welding to other Project Manager’s within the Petro-Canada Lubricants organization on several occasions.

I wouls recommend or use Hooper Welding’s Services without hesitation. should you have any questions, please contact the undersigned at 905-403-5723 or via email at dsharpe@suncor.com.

Yours truly,

david Sharpe

project Engineering

petro-canada Lubricants Inc.

Tel 905 403 5723

Fax 905 822 7602

dsharpe@suncor.com

Suncor Energy is the proud owner of Petro-Canada

Recently on our Diluent Recovery Unit project we contracted with Hooper to construct a cracked DOA Tower for our DRU unit for the Upgrader facility at our Long Lake facility which is located south of Ft McMurray Alberta. Near the end of the construction of this tower there were a number of changes made on the purchase order including adding insulation and changing our method of shipment from rail to truck. This meant that Hooper had to assist with the redesign of the tail lugs and shipping saddles and make the changes as required.

I am pleases to say that the tower was completed on schedule despite these late changes to the scope and Hooper consistently responded quickly and effectively to all requests on this order.

Regards,

Phil Downie

Manager, Strategic Procurement

Nexen Energy ULC

Dear chris,

I want to express Eastman’s appreciation of Hooper Welding’s overall performance and customer focus regarding the fabrication of the recent three large nickel-clad reactors. Your team of innovative design engineers, skilled welders, thorough quality management and customer focus regarding the fabrication of the recent three large nickel-clad reactors. Your team of innovative design engineers, skilled welders, thorough quality management and customer service representatives is a pleasure to work with. Additionally, your assistance in working through challenges oof minimizing project schedule, sourcing qualified alloy welding strip, developing rigorous QA of explosion clad plate and navigating logistics issues with the railroad were greatly appreciateed and allowed our teams to focus on other project issues.

It’s a pleasure to work with suppliers who suppliers who value the same expectations of quality, safety and commitment to doing the job right. We look forword to doing business with Hooper again in the near future.

Sincerely and thanks again,

Patrick Harnetty

Eastman Chemical Company

project Manager

Harnetty@Eastman.com

Hooper Weding Enterprises

In Appreciation of your Unwavering Service and Dedication to Pall Canada For Over 20 Years